In materials science and other industrial applications, surface analysis techniques are pivotal in uncovering crucial insights about the properties and behavior of various materials. The techniques employ advanced methodologies such as ToF-SIMS analysis to scrutinize the surface composition, structure, and properties at a microscopic level, offering invaluable information for optimizing performance, enhancing durability, and advancing innovation across diverse industrial sectors.

1. Analysis of Surface Contamination

Surface contamination analysis is a critical process that involves identifying and characterizing foreign materials present on the surface of substrates or materials. Whether you’re in manufacturing, quality control, or environmental monitoring, understanding surface contaminants is essential for ensuring product quality, performance, and safety.

Advanced techniques like tof sims offer precise and high-sensitivity analysis, enabling the detection of even trace amounts of contaminants. That allows for targeted mitigation strategies and regulatory compliance, enhancing product reliability and customer satisfaction. Also, unlike traditional techniques that may necessitate extensive sample treatments, this method is advantageous due to its minimal sample preparation requirements, making it efficient and cost-effective for surface contamination analysis.

2. Enhancing Quality Assurance Protocols

Accurate surface analysis techniques can help uphold quality assurance protocols and procedures to maintain high data integrity, reproducibility, and traceability throughout the analysis process. By using sensitive and reliable surface analysis techniques like the ToF-SIMS analysis, laboratories can accurately identify surface contaminants, characterize material compositions, and verify product quality, providing valuable insights into material properties and performance.

The meticulous approach empowers industries to establish robust protocols for ensuring the integrity and consistency of materials used in manufacturing, research, and development. That way, manufacturers can make informed decisions, enhance product performance, and instill confidence in stakeholders across various industries. The proactive approach improves product quality and mitigates risks while ensuring compliance with regulatory standards, ultimately contributing to long-term success and sustainability.

3. Investigating Organic Content of Samples

Surface analysis is crucial in investigating the organic content of samples, offering insights into their chemical composition and molecular structure. By employing advanced techniques such as ToF-SIMS, researchers can precisely identify and characterize organic compounds on the surface of materials. The analysis provides valuable information for various fields, including materials science, environmental science, and biomedical research, enabling researchers to understand better the properties and behavior of organic substances at the molecular level.

For example, in biomaterials research, surface analysis techniques like ToF-SIMS can investigate the composition of organic coatings on medical implants. That helps researchers to assess the implants’ biocompatibility, stability, and interaction with biological tissues. The information is critical for designing implant materials with improved performance and durability, ultimately leading to advancements in medical device technology and better patient outcomes.

4. Analysis of Glass Products

Surface analysis techniques are pivotal in accurate surface and 3D analysis of glass materials. By scrutinizing the composition and structure of glass samples, manufacturers can ensure adherence to stringent quality control standards. That enables the identification and mitigation of impurities or defects that could compromise the performance or durability of glass products.

For example, ToF-SIMS is crucial in analyzing opacifying inclusions in glass, a critical aspect of glass manufacturing. The inclusions, often microscopic, can affect the optical properties and structural integrity of glass products. By utilizing this technique, researchers can also precisely identify altered glass, allowing manufacturers to optimize production processes and enhance the quality of glass products. A detailed analysis helps maintain consistency and transparency in glass manufacturing, meet stringent industry standards, and improve product performance.

5. Investigating Surfaces Before and After Processing

By analyzing surface characteristics, such as topography, elemental distribution, molecular structures, composition, and cleanliness, before and after manufacturing or treatment processes, engineers and researchers can assess the effectiveness of processing methods. It also helps them identify potential issues or defects and refine production parameters for improved product performance and reliability. The approach surface ensures that surfaces meet desired specifications and standards, ultimately enhancing product quality and customer satisfaction.

By utilizing ToF-SIMS, industries can identify changes in micro- and nano-scale in surface chemistry, detect contaminants, and evaluate the effectiveness of surface treatments or processing methods, thus facilitating informed decision-making and quality assurance throughout the manufacturing process.

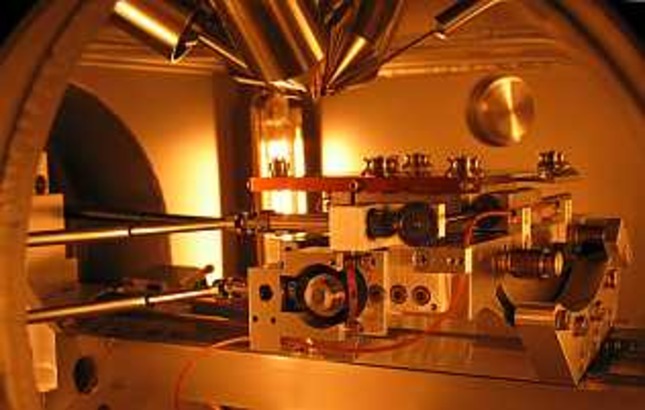

In conclusion, quality surface analysis techniques are crucial in diverse fields such as material science, environmental monitoring, and biotechnology. However, employing reliable methods like ToF-SIMS with high sensitivity can elevate the precision and efficiency of surface analysis, reducing the time and resources needed for sample preparation. Nevertheless, for this technique, it’s imperative to ensure that samples are vacuum-compatible to optimize the accuracy and reliability of the analysis results.